Injection mold temperature controller is used to control the mold temperature of injection molding machine and heat oil or water to the temperature required for product molding

1. Plastic has no physical quantity of heat shrinkage and cold shrinkage. There are often some defects such as shrinkage, bubbles, cracks, deformation, cracking, poor lightness, unsmooth, defects and so on outside the product forming process. The main reason for these defects is that the mold temperature before the product is formed is inappropriate, and the mold temperature cannot reach the product forming temperature during forming.

Engineering plastics such as PC, PA, PBT, etc. have high temperature requirements. The heat of the injection molding machine itself cannot meet the best temperature necessary outside the molding process. The injection mold temperature function can quickly increase the mold temperature, and can automatically schedule and ensure the mold temperature stability according to the temperature required by the material, so as to reduce the occurrence of defective products.

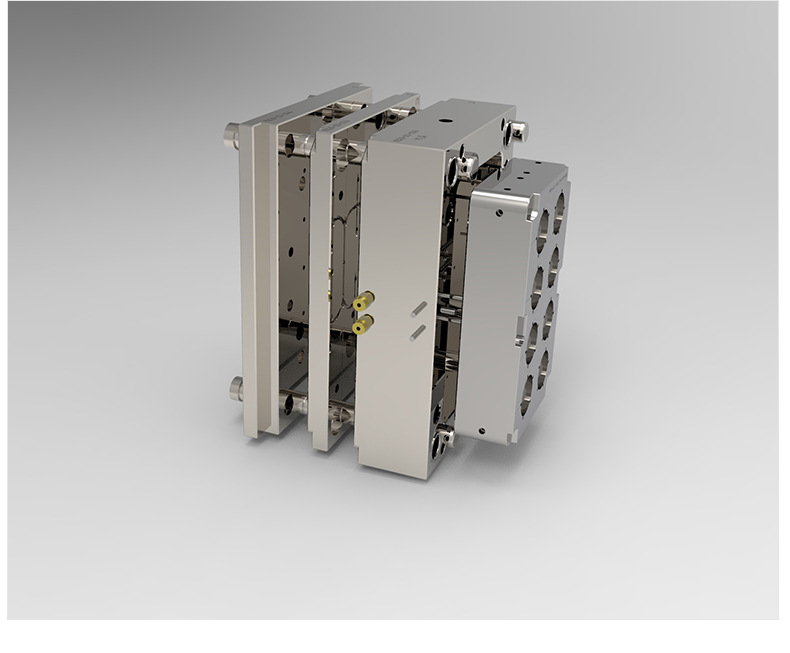

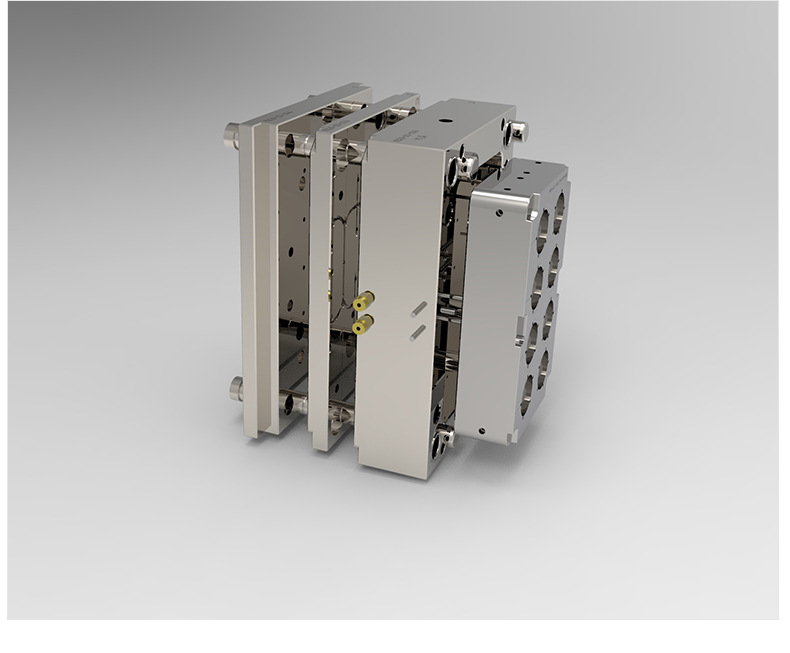

Injection mold warming machine

2. Keep the mold temperature in the best state, the mold will not overheat and stick to the mold, improve the dimensional accuracy and surface finish of the injection parts, prevent the cracks caused by the shrinkage of the injection parts, and better produce the thin-wall injection parts.

3. The effect of the mold temperature machine is to heat the mold, maintain its working temperature, ensure the quality of injection molded parts and shorten the production cycle. In the injection molding industry, mold temperature machine plays a decisive role in the quality and injection cycle of injection molded parts.

In the plastic industry, how to reduce the harm of mold temperature machine to product quality?

1. The heat balance control of injection mold the heat conduction of injection molding machine and mold is the key to the production of injection molded parts. Inside the mold, the heat brought by plastic (such as thermoplastic) is transferred to the material and the steel of the mold through thermal radiation, and to the heat-conducting fluid through convection. In addition, heat is transferred to the atmosphere and mold base through thermal radiation. The heat absorbed by the heat conducting fluid is taken away by the orant model temperature machine. The heat balance of the die can be described as: P = PM PS. Where p is the heat taken away by the mold temperature machine; PM is the heat introduced by the plastic; PS is the heat emitted by the mold to the atmosphere;

2. The purpose of controlling mold temperature and the influence of mold temperature on injection molded parts in injection molding process, the main purpose of controlling mold temperature is to heat the mold to the working temperature and to keep the mold temperature constant at the working temperature. If the above two points are successful, the cycle time can be optimized to ensure the stable and high quality of injection molded parts. Mold temperature will affect surface quality, fluidity, shrinkage, injection cycle and deformation;

3. The temperature control system consists of three parts: mold, mold temperature controller and heat conducting fluid. In order to ensure that heat can be added to or removed from the mold, all parts of the system must meet the following conditions: first, in the mold, the surface area of the cooling channel must be large enough, and the channel diameter must match the pump capacity (pump pressure). The temperature distribution in the cavity has a great influence on the deformation and internal pressure of the part. Reasonable setting of cooling channel can reduce the internal pressure and improve the quality of injection molded parts;

4. It can shorten the cycle time and reduce the product cost. Secondly, the mold temperature machine must be able to keep the temperature of the heat conducting fluid within the range of 1 ℃ - 3 ℃, which is determined according to the quality requirements of the injection molded parts. The third is that the heat conducting fluid must have good heat conduction ability. The most important thing is that it can import or export a large amount of heat in a short time. From a thermodynamic point of view, water is obviously better than oil.

Suzhou SINSA Mold Co., Ltd. is a professional manufacturer of precision molds and precision plastic parts in China. It is mainly engaged in the R & D, design and manufacturing of precision plastic molds, as well as injection molding and component assembly business. It is committed to providing customers with high-quality comprehensive services in mold design, injection molding plastic parts and product assembly.